The Actuation Laboratory is a new laboratory established in April 2023. We are working on research and development of field robots and service robots under the theme of -How can we successfully generate the motion of objects with mass and shape and the forces acting on them, and how can we utilize them for society?- This is true for cases such as when a robotic arm moves an object to a target location with high speed and repeatability, or when a robot itself reaches a location that is inaccessible to humans. We are studying the actuation of robots, and other physical objects to give them energy, convert them into motion, and manipulate them from the viewpoint of mechanism and control.

Research Policy

The two main research policies of our laboratory are as follows

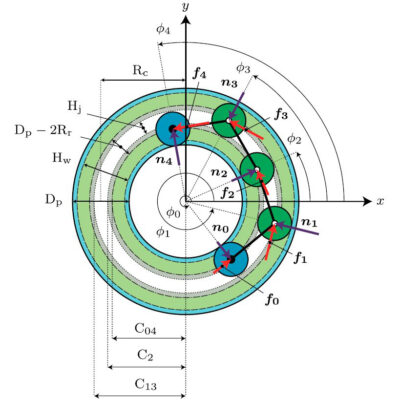

It is an attempt to create new value by adding new elements to existing technology. It is a method of adding more than the minimum number of elements to an existing technology, even if it costs a little more, to achieve a very high level of performance that did not exist before.

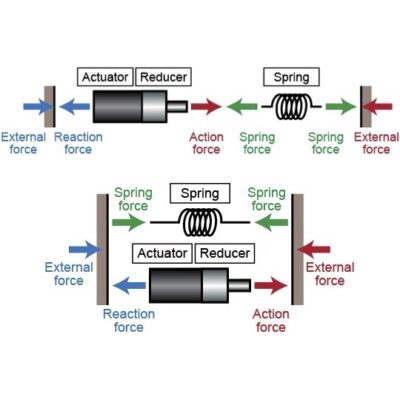

For example, a method called a series elastic actuator or a parallel elastic actuator that adds elastic elements to an existing motor falls into this category, as does a method called “redundant driven” or “coupled driven” that uses two motors to move a joint that has only one joint.

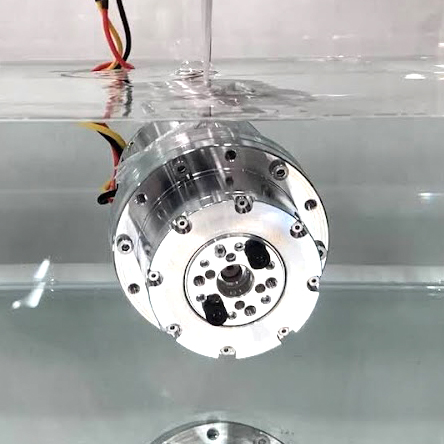

This approach is the opposite of the above. For example, recent electric motors tend to be integrated with mechanical and electrical components, and generally consist of a reduction gear, encoder, and driver circuit (PCB). If any one of these components can be reduced without compromising functionality, it may contribute to downsizing, weight reduction, and cost reduction. To put a finer point on it, the elimination of wiring, screws, lubricating oil, etc., would greatly change the conventional wisdom and potentially lead to solutions to problems. Above all, the simplification of the structure will lead to easier maintenance and lower costs.

For example, in the case of an articulated structure, replacing some of the active joints with springs or passive joints can be considered a part of this approach, as can a motor that can do so much work that it does not need a reduction gear, or enabling position control without the need for encoders.

Guidance Policy

In our laboratory, we value curiosity, inquisitiveness, and excitement. We encourage students to work on research themes that they are passionate about as much as possible, and try to create a system and environment that will lead to the creation of cutting-edge technology and growth as a human being.

We demand that our members take on challenges on a daily basis. This does not mean that we challenge them to do something outrageously unrealistic or risky. We mean that you should try things that you have never tried before in your life. It can be something small, something that someone else has already done, but if it is the first time in your life history, we think that it is a challenge.

The worst thing you can do is sit still and do nothing. It is important to keep walking little by little.

We encourage you to take on the following challenges as much as you can.

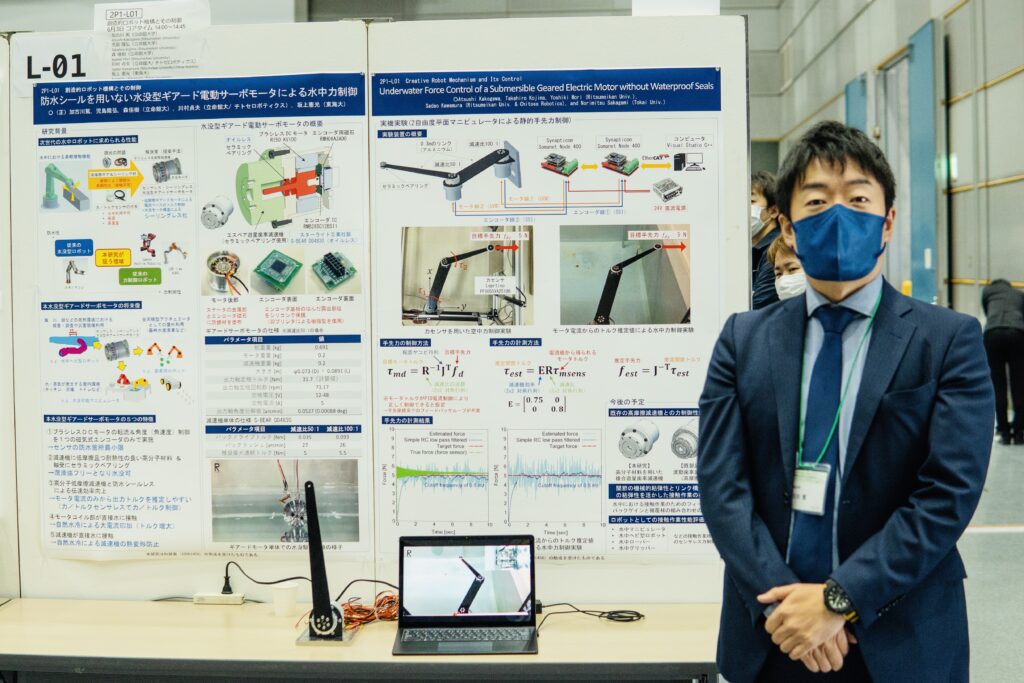

- Make a presentation at a domestic conference or an international conference (in English)

- Submission of papers to Japanese academic journals and international journals (in English)

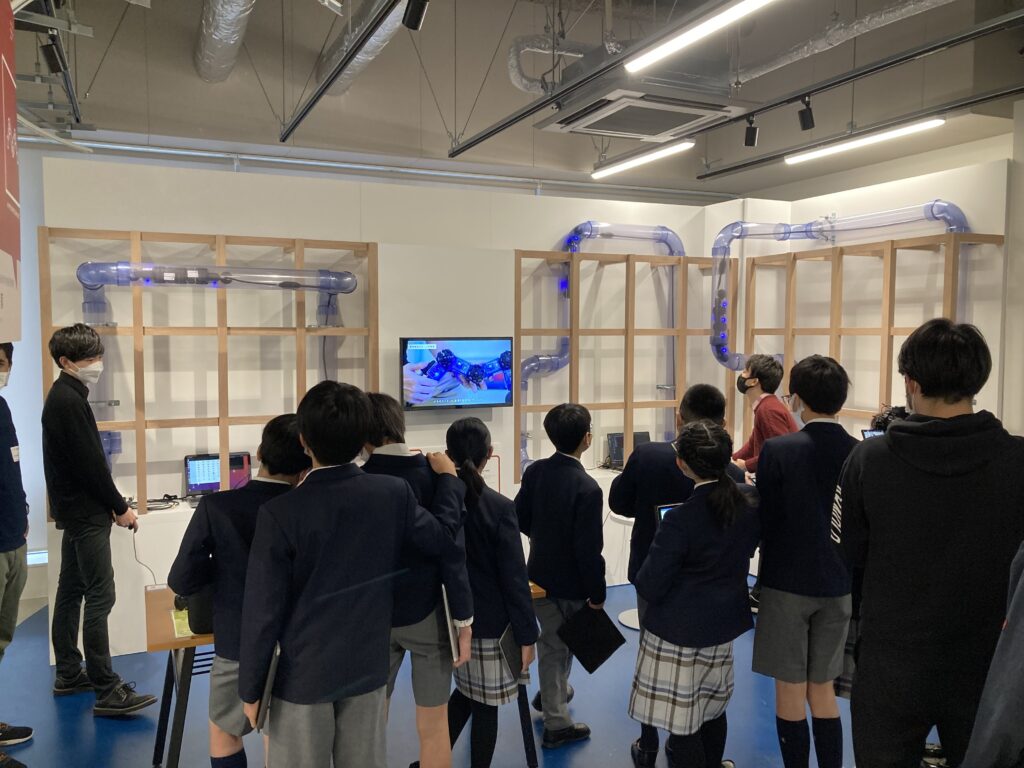

- Exhibit and demonstrate our robot at an exhibition

- Conduct joint research with private companies or research institutions outside the university

- Short-term study abroad at an overseas research institution to conduct research activities

It is very important to work on the principles of natural science. On the other hand, engineering differs from pure science in that one of its major objectives is to return basic research to society. No matter how brilliant a theory is developed, if it is not applied effectively in the world, it will be difficult to find value in it (* Of course, this does not mean that theory should be neglected).

However, while returning basic research to society is easy to say in words, it is extremely difficult to do in practice. In Japanese manufacturing industry, there is a common saying “Sen-Mitsu” (meaning that even if there are a thousand ideas, only three will bear fruit), and this applies to the field of robotics as well. In fact, it might be better to call it “Man-Mitsu” or “Oku-Mitsu”.

*Sen and Mitsu mean a thousand and three, respectively.

*Man and Oku mean ten thousands and hundred million, respectively.

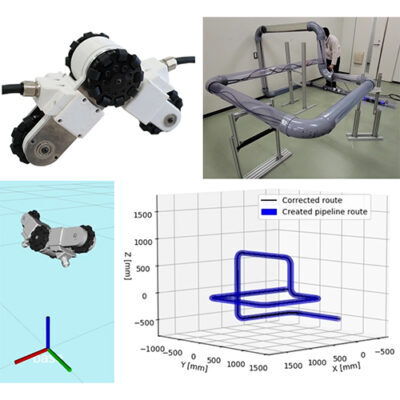

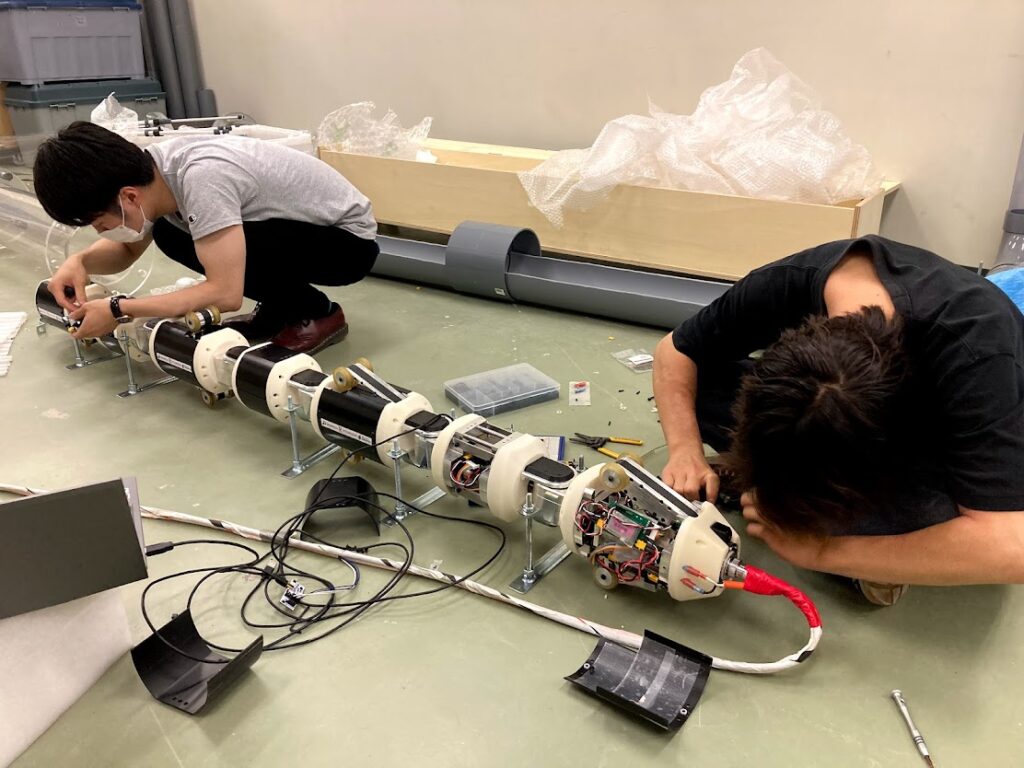

For this reason, we emphasize the importance of always being aware of the “Three Reals Philosophy,” that is, “actual site, actual thing, and actual reality,” in our research activities. We do not want you to work only with things that can be completed entirely on a computer in virtual, but we demand that you must always embody actual things that have mass and form, and consider them based on phenomena that are actually occurring. We also place great importance on conducting tests in a real environment (onsite), rather than only in the laboratory environment. Preparing for field tests and transporting the robot outdoors is very labor-intensive work, but the knowledge we gain from it is of great value.

In order to deal with problems for which there are no correct answers, we also attach great importance to “Done quickly is better than slow perfect” (in Japanese “巧遅拙速”). It is important to take time to think things through, but when dealing with actual machines and robots, in which multiple elements are intricately integrated, it is also very important to understand the phenomena by first making the actual robot in a short time, without thinking about anything difficult. We think it is also very important to understand the phenomena from this point of view when carrying out research and development.

Japan has a mature supply chain and an environment in which it is easy to obtain a wide range of industrial products. In addition, AM (Additive Manufacturing) technology, represented by 3D printers, has recently progressed. Japan is a very favorable environment for rapid prototyping.

In the course of research activities, there are many interesting and inspiring discoveries to be made. However, it is often physically and mentally demanding. Unforeseen circumstances are a daily occurrence. This is perhaps not surprising, as research and development is about working on things that no-one else in the world has done.

Research and development is not an activity where “the answer has already been decided and the shortest route to get there is to be found”. In many cases, there are multiple solutions that cannot be settled on a single one, or it is doubtful whether the solution itself even exists. And I believe that this is true not only in research and development, but also in human life.

We are repeatedly confronted with questions for which there are no answers, and each time we have to think for ourselves, find a compromise or convergence point, make a decision and take action. Graduation research and postgraduate research is a repetition of such things. But if you continue to face these things, you will have grown as a person by the time you realise it. If this is the result of your own hard work, we will support you in your decisions and actions. Let’s work hard together!

Equipment

A desk and computer are provided for each student.